We take a bottom-line approach to each project. Our clients consistently see increased traffic, enhanced brand loyalty and new leads thanks to our work.

The Time of Flight Diffraction is nowadays widely used in the welding examination and has universally been recognized as the technique that allows to obtain the highest POD (Probability of Detection) index among the ultrasonic methods, as it does not depend on the defect orientation (planar and/or three-dimensional).

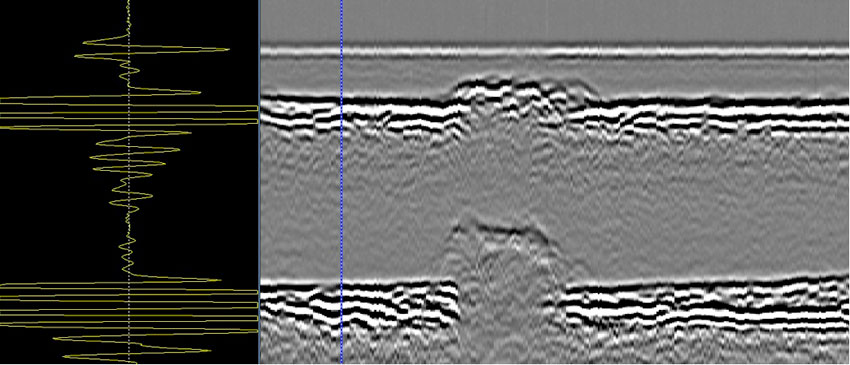

The detection is performed by the diffraction at the apices of a crack and/or along the cylindrical walls of a hole or a volumetric defect.

The TOFD technique can investigate a significant volumetric portion of the weld with a parallel-to-seam simple scanning line, so that the testing times are significantly reduced.

On the other hand:

Metalprove S.r.l. puts into practice an innovative method with two Phased Array probes arranged in a TOFD configuration, so as to generate in sequence different focal laws to ensure the entire volumetric inspection required by the codes (EN ISO 16828, EN ISO 10863, ASME Sec. V, ASME Sec. VIII, etc.).