We take a bottom-line approach to each project. Our clients consistently see increased traffic, enhanced brand loyalty and new leads thanks to our work.

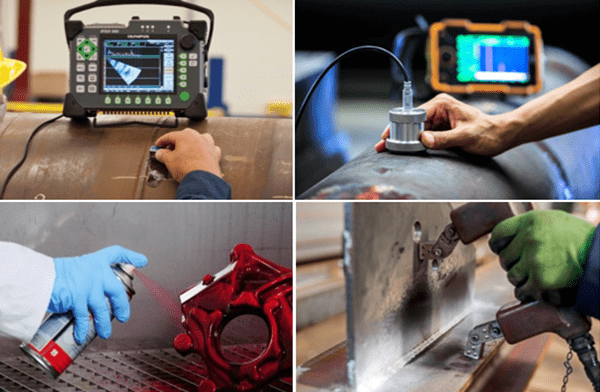

Non-Destructive Testing (N.D.T.) are techniques that allow to examine a material or component without affecting its integrity, ensuring quick tests by the ability to work directly onsite and get immediate results.

The typical purpose are identification, positioning, sizing and characterization of surface and volumetric discontinuities within items, during manufacturing and in-service stage.

Particularly, among the control systems which have the purpose of ensuring the reliability and the safety of even complex components, the diagnostic and monitoring methods of operational processes have been playing a more and more strategic role, not only for the prevention of anomalies and in-service breakdowns, but also in the set of testing and inspections required to qualify and/or certify products and plants.

Because N.D.T. are based on different physical principles, there is not any universal test method; rather, every technique is suitable more than others for a specific purpose. Commonly, the good inspection practices provide the combination of two or more testing methods.