We take a bottom-line approach to each project. Our clients consistently see increased traffic, enhanced brand loyalty and new leads thanks to our work.

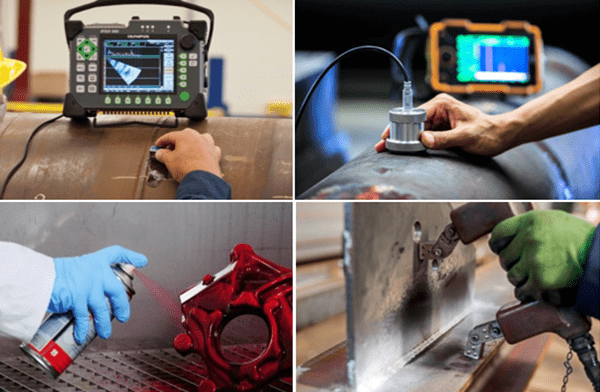

Non-Destructive Testing (N.D.T.) are techniques that allow to examine a material or component without affecting its integrity, ensuring quick tests by…

The Visual Testing (VT) has always applied, because it is based on the sight perceptions during various human activities, and in this…

The Penetrant Testing (PT) is a Non-Destructive Examination fundamentally based on visual inspection of the test surface after first application…

The principle of the Magnetical Particle Testing (MT) exploits the property of some materials, known as ferromagnetic, of attracting other…

The radiographic method (RT) makes use of a ionizing radiation beam directed towards the piece to be examined in order…

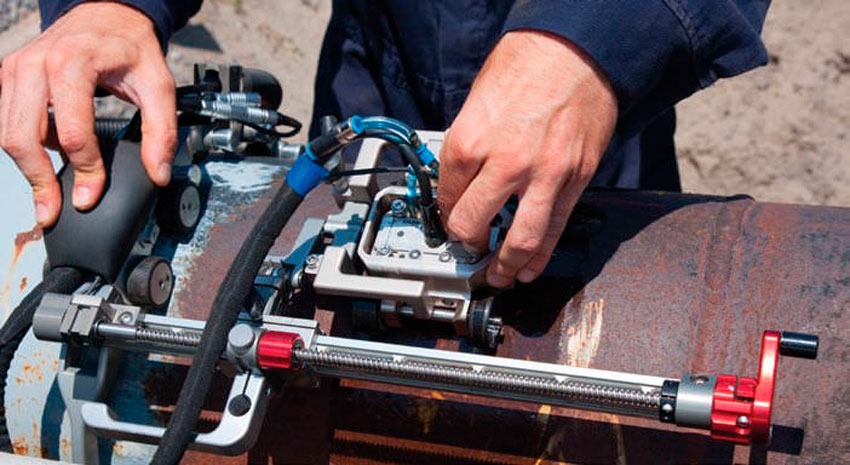

The Ultrasonic Testing (UT) is found on the ultrasonic wave propagation within the piece. As the light waves, even the…

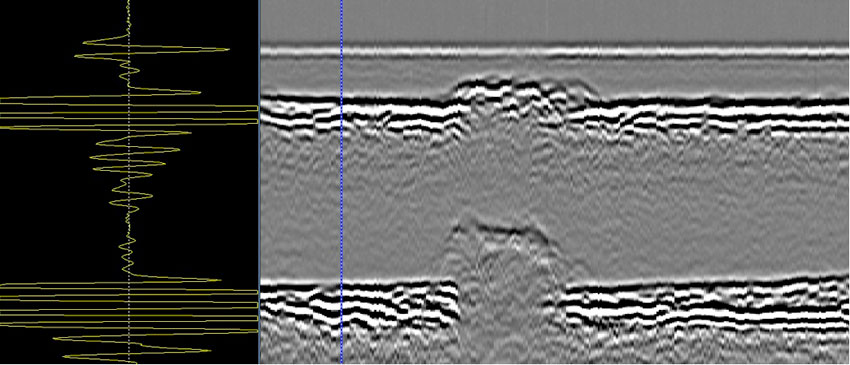

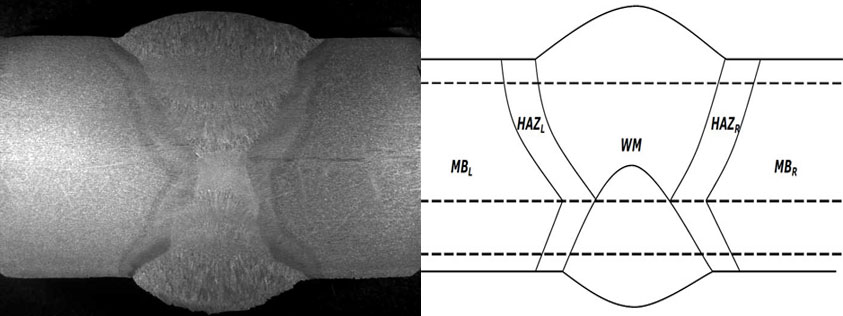

The Time of Flight Diffraction is nowadays widely used in the welding examination and has universally been recognized as the technique…

The Phased Array technique is characterized by the ability to electronically control the main parameters of an ultrasonic beam: angle and focusing.…

Hardness tests are non-destructive testing carried out in structural investigations, when it is important to identify possible alterations of the piece…

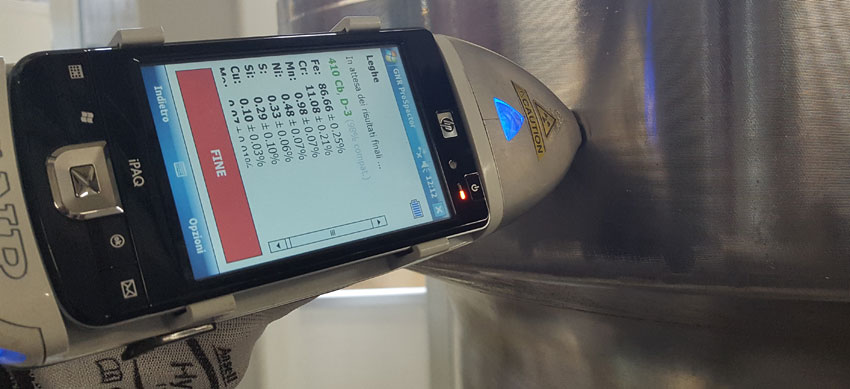

The Positive Material Identification (PMI) is an analytical technique that has the aim to clearly recognize a material. In mechanic industry…

Chemical, energy and processing plants are often subject to heat, aggressive media and high pressure. These circumstances demand steel with…

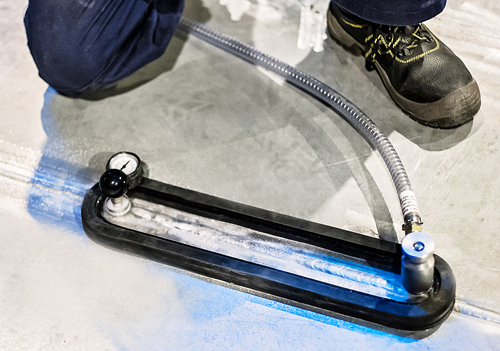

The Leakage Tests (LT) have the task to verify the sealing of vessels, when leakage of liquids is not acceptable (for…

The qualification courses for Non-Destructive Testing (NDT) personnel are designed to train participants in every method and prepare them for…

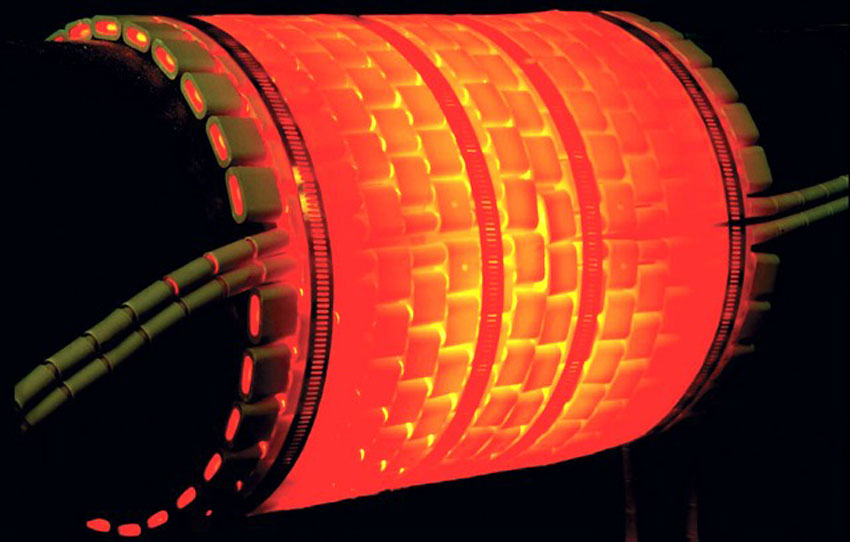

A heat treating includes a series of thermal processes carried out on metals or metal alloys in order to achieve a particular metallurgical structure and…

The preheating provides for localized achievement of a higher temperature than the ambient conditions, from both sides of the joint…

This term indicates the preheating keeping at the same temperature or higher temperature after the welding is completed. The main…

The thermal cycle induced by welding also causes mechanical effects; in fact, the metal parts that are heated are not…

The purpose of the expediting activity (or job progress monitoring) is to verify that suppliers, in the contest of a specific supplying,…

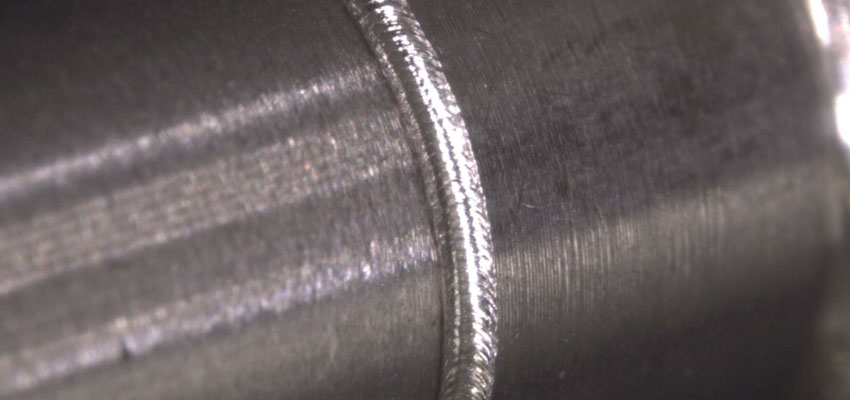

The welding processes are widely used to manufacture many industrial products and in some companies they are the most critical…

The criticality of the welding activities can be managed through the definition of appropriate process parameters; the documentation generally involves…

Through the work of an International Welding Engineer (I.W.E.), who is the highest level of qualification expected by the EWF…

It is clear that the fabrication of welds free from defects or, more realistically, with a quality level which is…

It is almost obvious to highlight the importance of using experienced personnel for successful welding. Therefore, the related qualification has…

The courses by Metalprove S.r.l. are the answer to the specific training needs of the companies. Training can be delivered…